Apex Dynamics, Inc. is a leader in the production of planetary gearboxes globally. Apex Dynamics, Inc. designed and constructed a technologically advanced, high speed, low backlash servo application planetary gearbox based on more than twenty years of combined manufacturing and marketing experience as well as the highest level of technical production capabilities. The customer receives the best high precision helical reducer at a competitive price thanks to our ground-breaking proprietary technology (more than 6 patents), which is backed by the only tip-to-toe 5-Year warranty currently available in the sector, which covers the seals and bearings as well.

In-Line Planetary Gearboxes

Precision helical planetary gears hardened to 840 HV and an internal gear that is machined directly into the gearbox casing are used in the construction of apex dynamics' helical in-line planetary gearboxes. They have patented input and output sealing as well as our proprietary input bearing system, which guarantees ideal concentricity. 3-100:1 ratio of availability.

Right-Angle Planetary Gearboxes

Precision helical planetary gears hardened to 840 HV and an internal gear that is machined into the gearbox casing are used in Apex Dynamics' helical right angle planetary gearboxes. Additionally, they have proprietary input and output sealing, case hardened and precision ground spiral bevel gears for accuracy and smoothness. 3-200:1 ratio of availability.

Spiral Bevel Right-Angle Gearboxes

These gearboxes have a wide range of uses because the spiral bevel gears meet at 90-degree angles to transfer the directed force along a straight angle rather than inline. These spiral bevel gears' helical teeth make them perfect for applications where the driving direction needs to be changed 90 degrees in order to drive the wheels. Our spiral bevel right-angle gearboxes include helical teeth, which greatly reduce noise and vibration. They are the perfect choice for applications where backlash or noise are key concerns.

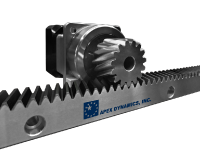

Precision Rack and Pinion

The precise rack and pinions available for purchase from Apex Dynamics USA are the best option for many automation applications. Ball screw systems can be replaced with rack and pinion systems, which have better force capabilities and can go farther without increasing inertia. In many situations, rack and pinion can be used to give cheaper cost and similar performance in place of linear motors. Electrical preload designs can be used to create highly precise rack and pinion systems for measurement systems and machine tools.